Environmental Policy and Labor Safety

Personnel Occupational Safety

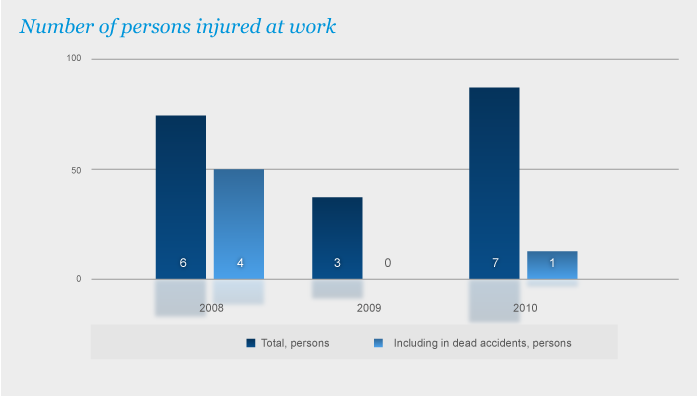

Comparative analysis of accidents on the Company's branches:

| Branch | 2008 | 2009 | 2010

|

|---|---|---|---|

| Vyborg PDN | 1 (light accident) | ||

| Gatchina PDN | 1 (light accident) | 1 (light accident) | |

| Cable network | 1 (serious accident) | 1 (light accident) | |

| Kingisepp PDN | |||

| Lodeynoe Pole PDN | 1 (fatal accident) | 1 (light accident) | |

| Luga PDN | 1 (light accident) | 1 (light accident) | |

| Novaya Ladoga PDN | 1 (fatal accident) | ||

| Suburban PDN | 2 (1 group fatal accident, 1 fatal accident) | 2 (serious accident) | |

| Tikhvin PDN | |||

| Executive office | |||

| TOTAL | 4

(6 injured, Including 4 dead) | 3

(3 injured) | 7

(7 injured, Including 1dead) |

Dynamics of common and lethal injuries and occupational morbidity (frequency rates):

| Rates | |||

|---|---|---|---|

| Rf – lost time accident frequency rate per 1,000 working employees, persons | 1,08 | 0,52 | 1,2 |

| Rs -accident severity rate, days per person | 60,3 | 38,3 | 60,6 |

| Rff – lost time fatal accident frequency rate per 1,000 working employees, persons | 0,72 | 0 | 0,17 |

| Rom – occupational morbidity rate per 1,000 working employees, persons | 0 | 0 | 0 |

In 2010, the following organizational and technical events planned by programs were carried out:

- Program of events for decrease in risks of origin of injury rates in JSC "Lenenergo" for 2009-2011" specified the following directions:

- Risks of infringement of a security status, reliability of professional activity, working capacity and levels of health of the personnel. Business processes and events for their decrease and elimination:

- Enhancement of the organization of a control system in the field of occupational safety, professional health and safety.

- Enhancement of methodical and standard system of provision of a occupational safety.

- Enhancement of technical, technological and material resources of operatively-corrective maintenance of electric networks.

- Increase in efficiency and quality of preparation of operative, operatively-repair and repair personnel.

- Development and introduction of intracorporate tools of propagation of safe work and injury rate decrease.

- Increase in efficiency and quality of psycho-physiological, social-psychological and medical provision of the personnel.

- Organization of work on accident prevention and occupational diseases.

- Introduction of international standard OHSAS "Management of production safety and personnel health".

- Risks of infringement of a security status, reliability of professional activity, working capacity and levels of health of the personnel. Business processes and events for their decrease and elimination:

- Program of events for decrease in risks in the field of professional safety and health for 2010-2012 specified the following directions:

- Provision of productive functioning of the system of management of professional safety and health according to the requirements of standard OHSAS 18001:2007.

- Non-admission of fatal accidents.

- Decrease in risk of danger of road accidents.

- Provision of accomplishment of requirements of the current legislation, standards and specifications in the field of occupational safety, professional safety and health.

- Decrease in risk of reception of electric traumas by JSC "Lenenergo" personnel.

- Decrease in quantity of cases of reception of electric traumas by third-party persons.

- Plan of measures for 2010-2012 on decrease in risks of injury rates of third-party persons specified the following directions:

- Decrease in risks of infringement of safety and reliability of the equipment.

- Decrease in risks of an injury rate of the personnel of contract organizations.

- Decrease in risks of an injury rate of third-party persons.

- Decrease in risks of an injury rate of children and teenagers.

In 2010, according to the approved programs, the following basic events for occupational safety were executed:

- The Order of JSC "Lenenergo" as of 23.07.2010 No.318 actualized the Policy of JSC "Lenenergo" in the field of occupational safety, professional safety and health.

- The Order as of 29.03.2010 No.127 modified the Control system of occupational safety (CSLS) of JSC "Lenenergo" regarding functions of employees in the field of occupational safety.

- The Order of JSC "Lenenergo" as of 27.05.2010 No.229 actualized the Rates of free issue of special clothes, special footwear and other means of individual defense to employees of JSC "Lenenergo" essentially improving the provision by protection frames of the personnel from sample rates, and also reducing risk of weight of an injury rate of the personnel, including from influence of electric arch.

- The Order of JSC "Lenenergo" as of 27.05.2010 No.500 approved the list of legislative and other requirements in the field of professional safety and health.

- In 2010, there was actualized and endorsed by Rostekhnadzor, and approved by the Order of JSC "Lenenergo" as of 04.02.2010 No.41 the Procedure for carrying out of work with the personnel in JSC "Lenenergo".

- In conformity with the approved Order necessary types of training of the personnel on occupational safety were conducted.

- The Order of JSC "Lenenergo" as of 29.12.2010 No.615 reviewed acting instructions on occupational safety of the Executive office.

- Specialists of the Department for PC and OT and ITR of Managements of branches of electric networks, heads and specialists of areas conducted regular checks of crews working on OTL, CL and SS with accounting of the Regulations on the check of workplaces (sudden check of workplaces)" and item 15 of the Procedure for of carrying out of work with the personnel in JSC "Lenenergo".

- Within the limits of work on introduction in JSC "Lenenergo" of the integrated system of management, in 2010 there was issued the Order as of 26.04.2010 No.181 "Identification of dangers and estimation of risks of professional safety and health" for calculation of risks in JSC "Lenenergo".

- There was issued the Order of JSC "Lenenergo" as of 01.11.2010 No.498 "About the approval of registers of critical risks in the field of professional safety and health of JSC "Lenenergo".

- According to the report of meeting on the analysis of functioning of system of quality management of JSC "Lenenergo" in branches, an additional practical training with employees concerning occupational safety, including the use of means of individual defense and organization of safe production of works was conducted.

- The system of the internal technical control (SITC) was implemented, specialists of the department for PC and OT conducted internal audits and target checks of 2 branches.

- In production divisions of branches there was conducted the pre-working trial (visual estimation of condition of employees, check of completeness of SIZ crews by the necessary and serviceable set of tools and devices prior to their departure to the place of works, acquaintance of employees with forthcoming work, study of the scenario of safe work, acquaintance with reviews of accidents, and etc.).

- At quarterly meetings with heads of branches there were considered actual issues on occupational safety, including decrease in risks of traumas of personnel and third-party persons.

- There were held two meetings with specialists on occupational safety and operation with participation of representatives of LLC "NPC Ekocertificate" and representatives of the trade-union organizations of JSC "Lenenergo" and the Territorial organization of SPB and LR of All-Russian "Electroprofsoyuz".

- There was implemented the program of provision of personnel of SIZ, SKZ, PBPR according to the approved AOPP, including fire-resistant complete sets, individual signaling devices of voltage, complete sets of protection frames and adaptations for work from the earth, without elevating on pylons by loosening devices.

- There was conducted the inventory of protection facilities and devices for safe performance of works.

- Methodical materials under the injury rate analysis went constantly to branches, an advanced experience of work without an injury rate, and printed materials on injury rate preventive maintenance, including children's ones.

- There were conducted agitation-explanatory events for non-admission of cases of an injury rate of third-party persons, including children, on objects of JSC "Lenenergo".

- There was almost implemented the program on equipment of production divisions of branches by new stands "occupational safety Corner", "the safety Screen" and dummies – training apparatus for training of the personnel to first-aid treatment acceptances.

- Necessary medical inspections and personnel vaccination were conducted.

- The personnel of the Department for PC and OT, specialists of branches participated in exhibitions and reviews of protection facilities and devices.

- Together with branches pre-production operation of new protection facilities and devices for safe production of works was conducted.

- The control of correct application of protection facilities and devices for safe production of works was led.

- The scheme of the linear control of safe operation of vehicles of the Company was developed and implemented.

- Additional training of drivers to actions in extreme situations on specialized rates on protective driving was carried out.

- Months of safe driving were conducted.

- Investigation of protections of power objects on their conformity to standard requirements was carried out. The revealed remarks were eliminated according to address repair programs.

- Meetings with representatives of contract organizations concerning observance of the procedure for admission of the sent personnel and personnel of СМО on objects of JSC "Lenenergo" were held. The control of work of the personnel of contract organizations was toughened.

- Meetings with administrations of municipal unions on population safety issue were held at their unauthorized finding on power network objects of JSC "Lenenergo".

- Based of the Regulations on estimations of readiness for safe carrying out of mass works, there were conducted checks of branches with registration of appraisal reports of readiness.

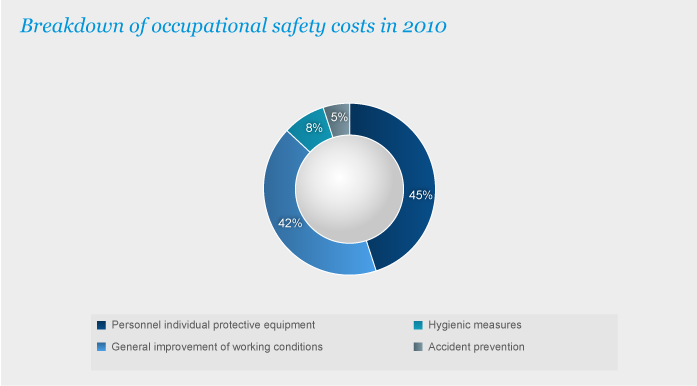

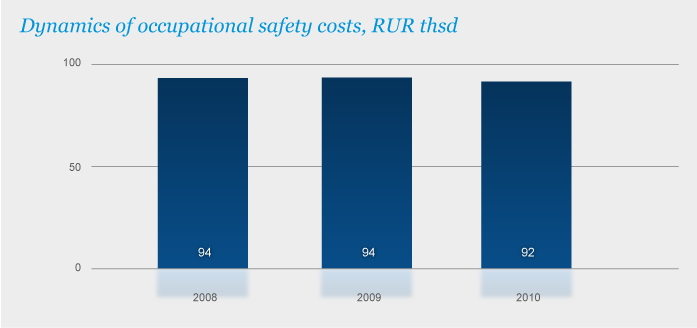

Occupational safety costs

| No | Indicator | Unit | 2009 | 2010 | 2010 /

2009 |

|---|---|---|---|---|---|

| 1. | Disbursed for occupational safety activities | RUR thsd | – 2,64 % | ||

| Including: | |||||

| 2. | for accident prevention measures: | RUR thsd | |||

| 3. | for hygienic measures to prevent occupational diseases: | RUR thsd | |||

| 4. | for measures to improve general working conditions: | RUR thsd | |||

| 5. | for procurement of individual protection equipment | RUR thsd | |||

| 6. | The sum of expenses for individual protection equipment as calculated per one employee | RUR per person | |||

| 7. | The sum of expenses for occupational safety as calculated per one employee | RUR per person |

The dynamics of growth and reduction in costs for occupational safety measures is conditioned by the following:

- decrease in accident prevention expenses is associated with the decrease in expenses on furnishing occupational safety offices, training and professional development of the employees, training aids and simulators;

- increase in expenses on hygienic measures for prevention of occupational diseases is attributed to the increase in expenses on scheduled medical inspections;

- decrease in expenses on general improvement of working conditions is attributed to the under-financing of events for the investment program and the repair program;

- insignificant reduction of expenses on individual protection equipment is stemming from the fact that the actual need to provide clothing decreased.

Certification of workplaces during the reporting period was not conducted.

In 2009 the Company purchased individual protection equipment and other safety equipment and accessories to the amount of RUR 50,181,804 including:

- 905 heat-resistant summer suits;

- 607 heat-resistant winter suits;

- 273 heat-resistant jackets-capes;

- 1,842 suits, coveralls, dressing gowns, raincoats of cotton (mixed fabrics);

- 1,476 pairs of heat-resistant summer footwear;

- 1,369 pairs of heat-resistant winter footwear;

- 1,138 pairs of ordinary summer footwear;

- 706 pairs of ordinary winter footwear;

- 3,362 hands, head and face heat-resistant means for electric arc protection;

- 17,495 hands, respiratory organs, head, eyes, face and ear protection means;

- 779 protection means against falling from height;

- 23,468 dermatological protection means;

- 1,145 other electricity protective means (grounding various, bars various, voltage indicators);

- 841 complexes of protective means and devices, including for work from the ground;

- 6,743 other means for safe production of works, including from dielectric rubber 6743;

- 1,292 tools isolating and screw-drivers dielectric;

- 995 first-aid sets;

- 14,997 safety signs and traffic signs.

Training of personnel was conducted according to the Procedures for carrying out of work with the personnel of JSC "Lenenergo" with a view of qualitative vocational training of the personnel, increase of its qualification and carrying out of instructing in safety of work".

For increase of professional skill of workers and working off of skills of safe production of works, intersystem competitions of the personnel of crews on servicing of high-voltage electric mains of distribution networks of JSC "Lenenergo" were held. The Best team participated in the all-Russian competitions organized by JSC "IDGC Holding".

Top